Steel

Steel is an Iron-Carbon alloy having a carbon content less than 2.0 percent and generally below 1.5 percent. It usually contain substantial quantity of manganese.

Physical properties of steel

The important physical properties of steel that concern the engineers are

Strength

Elasticity

Stiffness

Ductility

Malleability

Brittleness

Factor effecting physical properties of steel:

The principal factors influencing the physical properties of concrete are

1. The carbon content.

2. The percentage of silicon, sulfate, phosphorus, manganese and other alloying elements.

3. The heat treatment and mechanical working.

Comparison between steel and concrete :

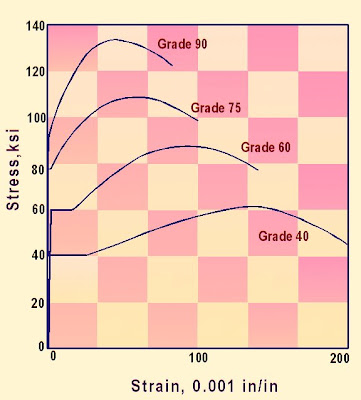

Steel is a high-strength material compared to concrete. The useful strength of ordinary reinforcing steel in tension as well in compression, i.e. the yield strength, is of the order of 10 times the compression strength of common structural concrete, or of the order of 100 times its tensile strength. On the other hand, steel is a high-cost material as compared with concrete.

Function of steel as reinforcement:

The two materials are best used in combination if the concrete is made to resist the compression stresses. Thus, in reinforced-concrete beams the resists the compression force, longitudinal steel bars are located close to the tension face to resist the tension force, and frequently additional steel are disposed that they resist the inclined tension stresses which are caused by the shear force in the webs of beams.However, reinforcement is also used for resisting compression forces primarily where it is desired to reduce the cross-sectional dimension of compression members, as in the lower floor columns of multistory buildings. Even such necessity is not exist, a minimum amount of reinforcement is placed in all compression members to safeguard them against the effects of small accidental bending moments which might crack and even fail an unreinforced member.

Steel - Concrete Surface Interaction :

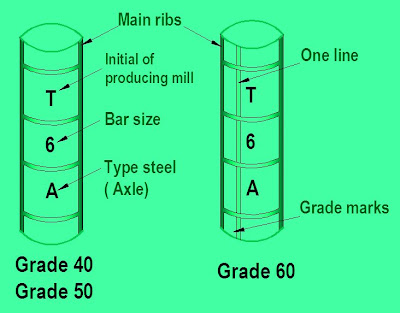

For most effective reinforcing action, it is essential that steel and concrete deform together, i.e., that there be a sufficiently strong bond between the two materials so that no relative movements of the steel bars and the surrounding concrete occur. This bond is provided by the relative large chemical adhesion which develops at the steel concrete interface, by the natural roughness of the hot - rolled reinforcing bars and by the closely spaced rib-shaped surface deformations with which reinforcing bars are furnished in order to provide a high degree of interlocking of the two materials.

Additional features related to combined performance of two materials are following:

1) The thermal expansion coefficient of the two materials are

Steel - 0.0000065

Concrete - 0.0000055

These values are sufficiently close to forestall cracking and other undesirable effects differential thermal deformations.

2) While the corrosion resistance of bare steel is poor, the concrete which surrounds the steel reinforcement provides excellent corrosion problems and corresponding maintenance costs.

3) The fire resistance of unprotected steel is impaired by its high thermal conductivity and by the fact that its strength decreases sizably at high temperatures. Conversely the thermal conductivity of concrete is relatively low. Thus damage caused by even prolonged fire exposure, if any, is generally limited to the outer layer of concrete, and a moderate amount of concrete cover provides sufficient thermal insulation for the embedded reinforcement.

Types of Reinforcements :

Steel is used in two different ways in concrete structure :

- as reinforcing steel

- as prestressing steel

Reinforcing steel :

Reinforcing steel is placed in the forms prior to casting of concrete. Stresses in the steel, as in the hardened concrete, are caused only by the loads on the structure, except for possible parasitic stresses from shrinkage or similar causes.

The most common type of reinforcing steel is in the form of round bars. They are available in a large range of diameter, from about 1/4 to 1.375 in. These bars, with the exception of 1/4 in. size, are furnished with surface deformations fpr purpose of increasing bond strength between steel and concrete. Minimum requirements for these deformation (spacing and projection etc.) have been developed in lengthy experimental research and are specified in ASTM specification A305.

Reinforcing steel is placed in the forms prior to casting of concrete. Stresses in the steel, as in the hardened concrete, are caused only by the loads on the structure, except for possible parasitic stresses from shrinkage or similar causes.

The most common type of reinforcing steel is in the form of round bars. They are available in a large range of diameter, from about 1/4 to 1.375 in. These bars, with the exception of 1/4 in. size, are furnished with surface deformations fpr purpose of increasing bond strength between steel and concrete. Minimum requirements for these deformation (spacing and projection etc.) have been developed in lengthy experimental research and are specified in ASTM specification A305.

good point. this post is very informative especially to students like me.

ReplyDeleteany idea how much does a steel shrink when its cold? or how much does a steel contract when the weather is so hot?

ReplyDeletenice job

ReplyDelete