Sand drains

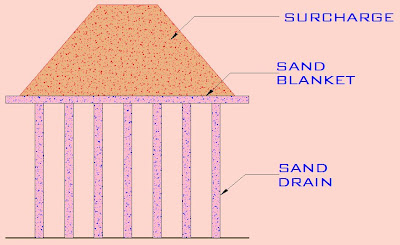

Sand drains is a process of radial consolidation which increase rate of drainage in the rate of drainage in the embankment by driving a casing into the embankment and making vertical bore holes. These holes is back filled with suitable grade of sand.

Process of construction of drains

The driven casing is withdrawn after the sand has been filled. A sand blanket is placed over the top of the sand drains to connect all the sand drains. To accelerate the drainage, a surcharge load is placed on the sand blanket. The surcharge is usually in the form of dumped soil.

Mechanism of consolidation

The pore water pressure is increased by the applied surcharge load in the embankment. The drainage occur in the vertical and horizontal directions. The horizontal drainage occure because of sand drains. The sand drains accelerate the the process of dissipation of excess pore water created by the surcharge.

Spacing of drains

The drains are generally laid either in a square pattern or a triangular pattern. The spacing (s) of the drains is kept smaller than the thickness of the embankment (2H) in order to reduce the length of the radial drainage path.

Sand drains is a process of radial consolidation which increase rate of drainage in the rate of drainage in the embankment by driving a casing into the embankment and making vertical bore holes. These holes is back filled with suitable grade of sand.

Process of construction of drains

The driven casing is withdrawn after the sand has been filled. A sand blanket is placed over the top of the sand drains to connect all the sand drains. To accelerate the drainage, a surcharge load is placed on the sand blanket. The surcharge is usually in the form of dumped soil.

Mechanism of consolidation

The pore water pressure is increased by the applied surcharge load in the embankment. The drainage occur in the vertical and horizontal directions. The horizontal drainage occure because of sand drains. The sand drains accelerate the the process of dissipation of excess pore water created by the surcharge.

Spacing of drains

The drains are generally laid either in a square pattern or a triangular pattern. The spacing (s) of the drains is kept smaller than the thickness of the embankment (2H) in order to reduce the length of the radial drainage path.

Zone of influence

The zone of influence of each drain in a triangle pattern is hexagonal in plan, which can be approximated by an equivalent circle of radius R, where R = 0.525 S. In case of a square pattern, the radius of circle of influence R is equal to 0.554 S. The radius of the sand drain is represented by rw.

Theory of sand drains

The theory of sand drains was given by Rendulic (1935) and Barron (1948). Later, Richart (1959) summarized the theories. Depending on the type of strain, there are two cases.

1) Free strain case.

2) Equal strain case.

1) Free strain case

If the surcharge load placed over the sand blanket is flexible, free strain case occurs. In this case, there is uniform distribution of surface loads, but the settlement at the surface is uneven.

2) 2) Equal strain case

This case occurs when the surcharge applied is rigid, such as heavy steel plates. In this case, the settlements are uniform, but the distribution of pressure is non-uniform.

Limitation of sand drain application

Following consideration is not included in design of sand drains:

1) 1) Secondary consolidation is not taken into account in the design of sand drains. In fact, the sand drains are ineffective in controlling the secondary consolidation for highly plastic and organic soils.

2) 2) In case of deriving equation for effectiveness of sand drains, it is not considered that the excess pore water pressure developed, actually in soil where sand drains are exist, is generally less than that of the case having no sand drains. Sand drains tend to act as weak piles and reduce the stresses in the clay.

3) The typical design parameter for sand drain may vary as below :

a) Spacing of sand drains, S = ( 2 ~ 5) m

b) Depth of sand drains, 2 H = (3 ~ 35) m

c) Radius of sand drains well, rw = (0.2 ~ 0.3) m

d) Thickness of sand blanket = (0.6 ~ 1) m

Interesting blog. This is one of my favorite blog also I want you to update more post like this. Thanks for sharing this article.

ReplyDeleteSand Dealers in Chennai

Informative, Kindly give the reference for sand blanket thickness 0.6-1m.

ReplyDelete