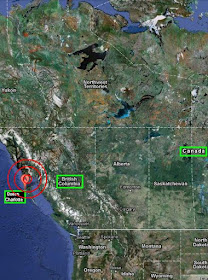

Tipaimukh is located at South-Western Manipur bordering Mizoram. Most of the people living here are actually of minority Hmar tribe. The proposed Tipaimukh dam is to be located 500 meters downstream from the confluence of Barak and Tuivai rivers. It is a huge earth dam (rock-fill) having an altitude of about 180 M above the sea-level with a average reservoir capacity of 15.5 BCM.

The proposed Tipaimukh Dam site is at Monipur-Mizoram boarder in India. The area is surrounded by regions of high seismicity, which include the Himalayan Arc and Shillong Plateau in the north, Burmese Arc, Arakan Yoma anticlinorium in the east and complex Naga-Disang-Haflong thrust Zones in the northeast. The major Dauki Fault system along with numerous subsurface active faults and a flexure zone -- called Hinge Zone -- lie in the vicinity of the dam site. Monipur-Mizoram states are part of India Myanmar Hill Range formed by the interaction of the Indian, Eurasian and Myanmar Plates. These weak regions are believed to provide the necessary zones for movements in the North

|

| Barak River and Tipaimukh Dam |

-East India Region, which experienced many major earthquakes during last 150 years and has been affected by small earthquakes occasionally.

The dam site and adjoining areas lie in the most seismically active zone in the world. Historical records show that at least eight large earthquakes in the region have occurred during last one hundred and fifty years, with three of them having magnitude of more than 8.

The northern and eastern regions of India covering Meghalaya, Assam, Monipur, Mizoram and north-eastern Bangladesh are so related morphotectonically that the analysis of seismicity of the Bangladesh region without considering adjoining areas will be incomplete and unrealistic. All the great earthquakes located in India have affected the north-eastern region of India and caused enormous damage. The western Assam earthquake of 1897 is probably the most documented. The intensity distribution of its surface effects shows that the damage represented by Mercali scale (ME) VIII-IX lies in the vicinity of the Tipaimukh dam site. Return of such an earthquake in the region is not at all unexpected since the dam site is situated in the most fragile ge0-tectonic region.